Application

Die casting is a metal casting process characterized by forcing molten metal under high pressure into a mold cavity. The molds, commonly referred to as dies, are typically crafted from high-strength alloys, making the process somewhat similar to injection molding. Die-cast components are often made from non-ferrous metals such as zinc, copper, aluminum, magnesium, lead, pewter, and tin. Depending on the type of die casting, either a cold chamber or a hot chamber die casting machine is required.

Due to the high cost of casting equipment and molds, die casting is primarily utilized for the mass production of large quantities of components. Producing individual die-cast parts is relatively straightforward, with a low incremental cost per unit. Die casting is especially well-suited for manufacturing a high volume of medium- to small-sized components, making it one of the most widely used casting techniques. Compared to other casting methods, die casting provides smoother surface finishes and greater dimensional accuracy.

Woodworking Machinery Parts

Pneumatic Tools

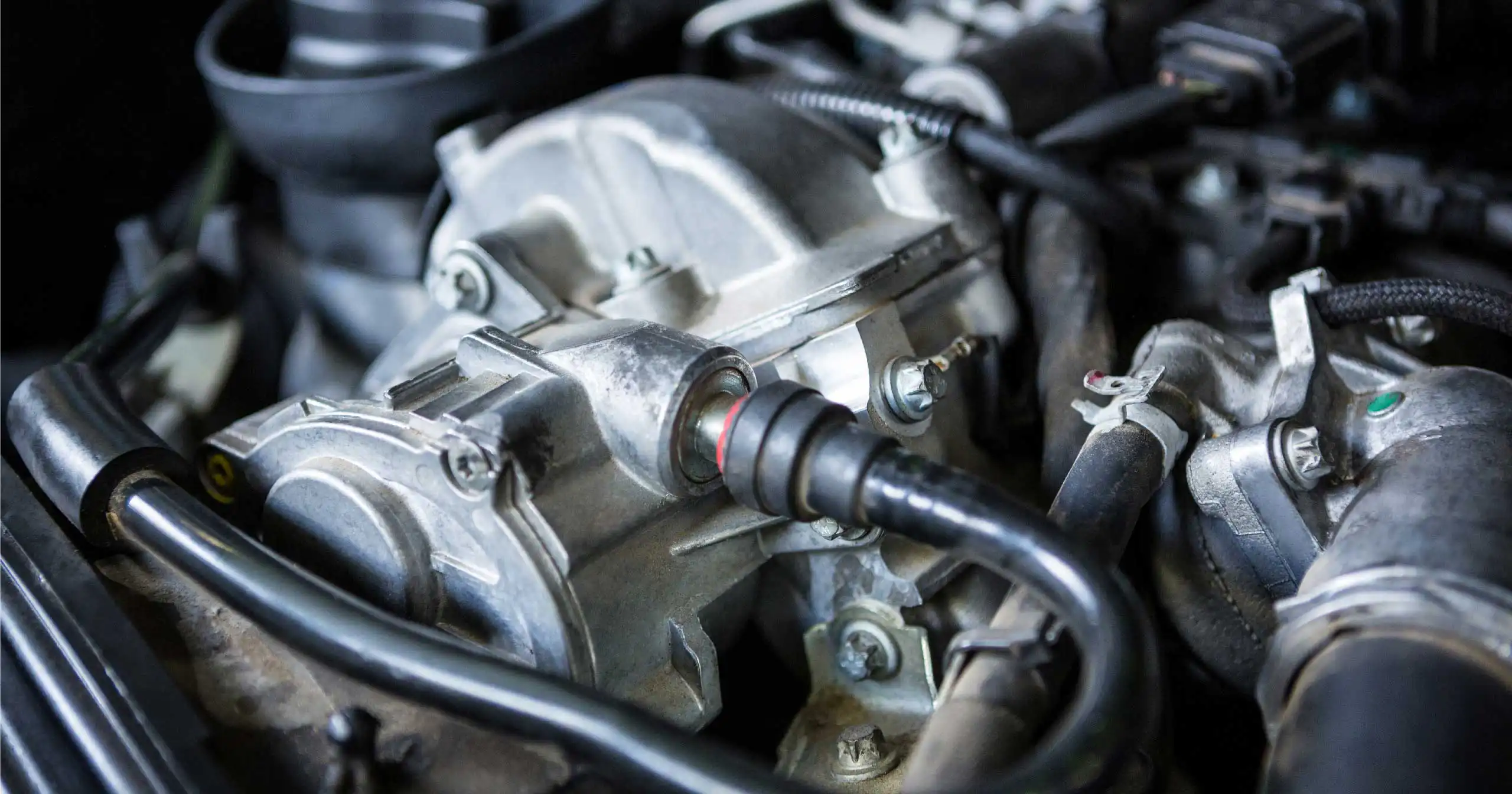

Automotive and Motorcycle Parts

Electric Tool Parts

Motors Parts

Switch Devices Parts

Communication Components

Sports device& lighting Parts

Lighting Industry